Weihai WenTai automation equipment co., LTD

Phone:0631-8263819

Fax:0631-8263819

Email:sunkangcheng888@163.com

Address:Middle section of Tang Nan Industrial Park, Wendeng District, Weihai, Shandong

Pneumatic Conveying System 0f Raw Materials And Its Advantages

Click:4406 │ Date:2022/4/13 │ Return

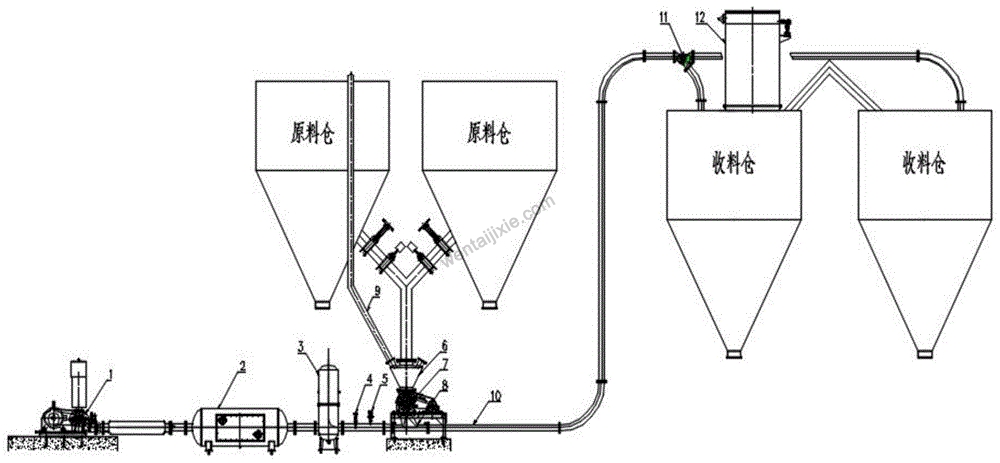

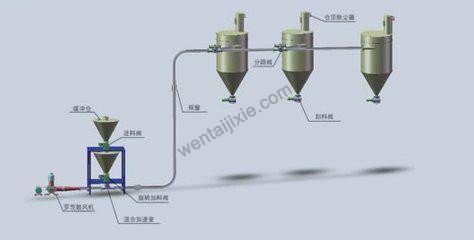

According to the combination of equipment, pneumatic conveying can be divided into three types: Suction conveying type, pressure conveying type and mixed type. Its main equipment includes feeder, separator (or discharge) , wind off, dust collector, feeding pipe, air duct and high-pressure Fan, etc. .

Suction pneumatic conveying device: air working under negative pressure, materials and dust will not escape; simple material supply, can be centralized from a few places to a transport; suitable for large-scale or stored in the deep, low-level materials transport; The strict requirements of the discharge device and dust collector are high, the conveying capacity and distance are limited, and the power consumption is higher than that of the compressed air type.

Pressure pneumatic conveying device: suitable for long-distance and large-flow conveying; unloader has simple structure and can convey materials to several places at the same time; can prevent impurities from entering the system; air works under positive pressure and is easy to cause dust to spread out, therefore, although the power consumption is lower than the suction type, its application is still limited.

The mixed type pneumatic conveying device which is composed of a suction conveying type and a pressure conveying type. Fan in the middle of the pipeline, both the advantages of suction-type and pressure-type, from a few suction material and pressure to discharge far away. But its structure is complicated.

The advantages of pneumatic conveying: simple structure, low equipment costs, flexible process layout, less land, easy to achieve automation; the conveying of materials is carried out in the pipeline, the whole system is sealed, can effectively control dust flying, reduce material loss; The utility model can carry out the technological operation of removing impurities, removing dust, cooling, air cleaning and drying of materials while completing the conveying operation; the pipeline is continuously washed by the flowing air flow, the microorganisms are not easy to reproduce and the pests are reduced; the conveying quantity is large, the operation is simple and the maintenance is convenient; Labor saving.

The main disadvantage of pneumatic conveying is high energy consumption, not easy to transport high humidity, viscosity or fragile materials.

- 2020 Shanghai CBB Exhibition Weihai WenTai Company Exhibit——Malt and Rice Handling System

- The First Day Of 2018 Shanghai CBB Exhibition

- Water Treatment Equipment For Craft Beer(Shanghai CBB Exhibition Weihai WenTai Company Exhibit Ⅳ)

- Craft Beer Malt Mill(Shanghai CBB Exhibition Weihai WenTai Company ExhibitⅢ)

- Bucket Elevator (Shanghai CBB Exhibition Weihai WenTai Company Exhibit Ⅱ)

- Malt Wet Mill(Shanghai CBB Exhibition Weihai WenTai Company Exhibit I)